Cleaner oceans with automation and technology

Evac’s solutions help the marine industry keep the oceans clean.

Published 12.2.2020

Published 12.2.2020

Commissioning, maintenance and installation projects regularly take Makron’s employees to the world’s largest luxury cruise ships that make use of cleantech systems supplied by its customer Evac.

Evac is the world’s leading provider of integrated water and waste management systems, as well as corrosion-protection systems, for the marine, offshore, and building industries. While the company has its head office in Finland, its operations are global. Makron supplies comprehensive automation solutions and mechanical manufacturing for Evac’s systems.

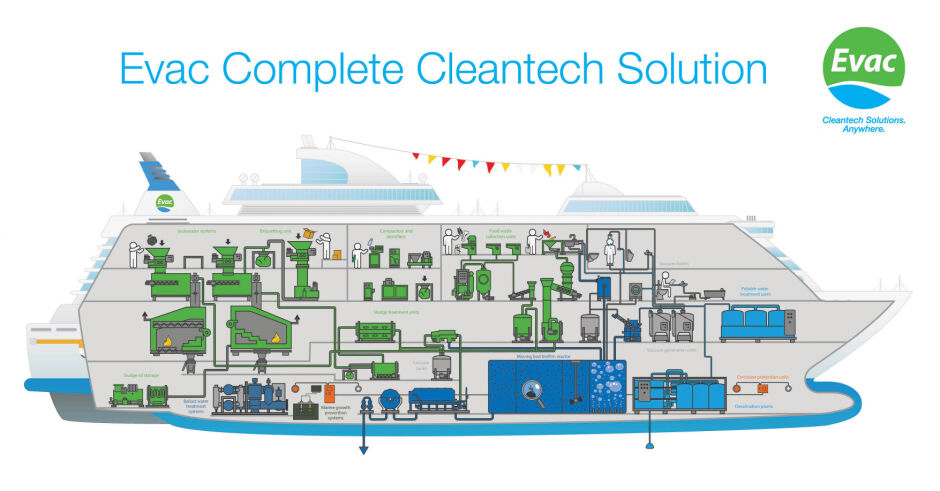

Evac’s cleantech solutions help the marine industry keep the oceans clean by collecting and processing wastewater and wet and dry waste generated on the cruise ship. Using a vacuum pump system to collect and transfer waste into collection tanks, Evac’s vacuum toilets and waste collection systems help preserve water. With Evac’s biological or electrolytic solutions for the purification of wastewater, from 30 to as many as 100 cubic meters of wastewater per hour can be processed on a large cruise ship. These waste management solutions reduce the volume of waste by compacting, shredding, briquetting, and burning. Cruise vessels also need drinking water and other freshwater, which are generated from seawater with freshwater generation systems. In addition, Evac supplies ballast water management, marine growth prevention, and corrosion protection solutions.

Collaboration between Makron Automation and Evac began with the delivery of control cabinets in 2004. Soon Makron was given more responsibility over the projects: it was involved in the design of the MBR wastewater treatment system from the get-go, after which the companies collaborated in the development of the vacuum waste solution. In recent years, Makron has contributed to several product development projects, of which the development of moving bed biofilm reactors (MBBRs) used for treating wastewater was the most significant one.

Evac relies on Makron’s automation expertise. “Makron Automation’s experience is valuable to us because they know the devices and processes and have been involved in our product development projects for more than a decade,” says Tuukka Farin, VP for Supply Chain & Sourcing at Evac.

A typical automation project involves electrical and automation design, programming, electrical control cabinet manufacturing, and installation and commissioning tasks. The collaboration has extended from automation services to mechanical engineering and manufacturing. Last year, Makron’s factory in Estonia produced 52 Evac devices, which were installed on four vessels. The manufacturing process includes assembly work and electrification.

Evac’s marine sector projects typically last for several years and numerous Makron employees participate in them at various stages. For example, as early as 2017, Makron supplied the first control cabinets and boxes for a cruise ship, which was recently completed.

Makron contributes its expertise to Evac’s automation design and product development projects. “Our latest projects involved the preparation of documentation related to the electrotechnical standardization of Evac’s systems and the development of automation technology covering all the systems,” explains Petri Saarinen, Makron’s key account manager. As a long-term partner, Makron has the ability to harmonize various systems’ automation and support Evac in its goal to create even more efficient comprehensive solutions.