BE Group Oy Ab is a steel service company that supplies metal to customers in the engineering and construction sectors. Its product range includes steel, stainless steel, and aluminum in various forms: bars, sheets, tubes and beams. Customers can also order cut-to-size and processed products. The parent company BE Group AB is a listed Swedish company. The Finnish company’s headquarters and one of its steel service centers are located in Lahti.

Stacker crane is the cornerstone of intralogistics

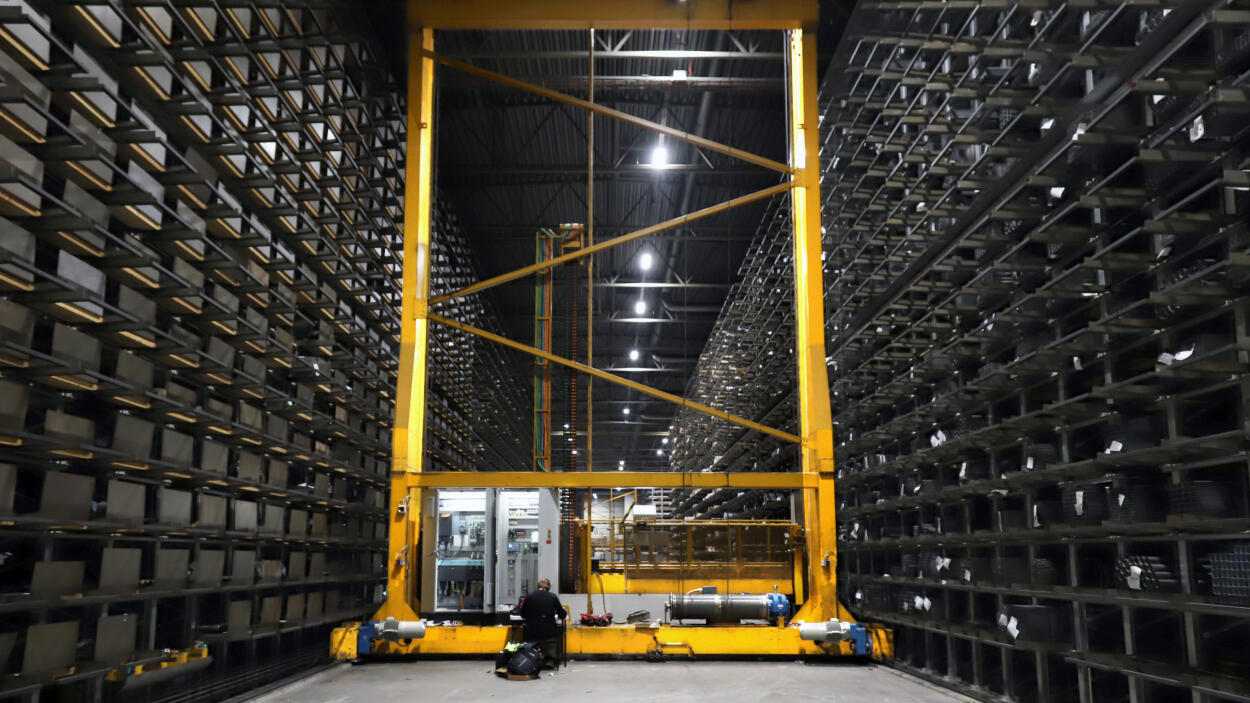

At the steel service center in Lahti, products are stored in shelving units, from where they are picked for delivery to customers. The spacious high-bay warehouse has its own shelving units for long steel products and sheet products. Each shelving area has its own stacker crane for transporting goods. The stacker crane that transports long steel products serves 2,265 storage spaces.

“The reliability of the stacker crane is essential because it is used in three shifts around the clock,” says Jani Tyni, the warehouse foreman. “We pick two and a half thousand order rows every week. Most orders are dispatched the following day.” The stacker crane being out of service even for a single day due to a major fault would affect deliveries for the whole week.

Built in 2003, the stacker crane contained old components and had developed faults that were not easy to identify. BE Group was aware that it needed a reliable and experienced partner to modernize the stacker crane in order to get it up and running quickly.

Makron’s solution: new automation and control system

BE Group selected Makron to design and implement the modernization of the stacker crane. “During the quotation process, we were impressed by how Makron handled the matter,” says Production Manager Tomi Hiltunen. “We knew Makron from previous modernization projects and therefore we were confident that this project would also be successful,” he continues.

Makron analyzed the necessary changes and designed modern control and safety solutions for the stacker crane. The stacker crane’s motor drives and their control systems were overhauled with solutions from Siemens’ TIA Portal programming environment. Mechanical problems with the device were also fixed in this connection.

Safety first and foremost

Safety was a central aspect of the project. After the renovation, the stacker crane is safer to service, as safety barriers and safety controls were added to the service platform. Safety at the picking points was improved by adding netting and installing new light curtains.

Improvements to safety and workflow were combined at the picking point, where the stacker crane brings cassettes loaded with products. Scanners now monitor a slightly wider safety zone, so that movement is stopped when people are within a contact distance. And when people leave the safety zone, the scanners activate an automatic acknowledgement after a short delay. No one has to go and manually press a button to get the cassette moving again.

Modernization completed on a tight schedule

BE Group and Makron decided to schedule the implementation and commissioning of the modernization for the Christmas period, which is the most convenient time for disrupting deliveries, as many customers have their maintenance shutdown then.

Makron’s electricians carried out the required electrical installations. Makron built the new control cabinet for the stacker crane in their facilities. An electrician made changes to the electrical control cabinets outside the shelving units on-site.

Once the installations were complete, Makron’s automation engineers carried out testing and commissioning of the stacker crane’s control system, safety systems, and service tracks. The stacker crane was brought into operation on schedule—even ahead of it.

Automation fixes mechanical problems

BE Group Oy Ab’s CEO Petteri Korpioja praises Makron’s ability to solve problems. The change that is evident within a hearing distance is the stacker crane’s silent operations, as before it made a loud rumbling noise whenever it moved. The noise was caused by mechanical problems: the track was worn and the rails were not perfectly straight, which caused the stacker crane to run at an angle. “We were able to solve the mechanical problems with automation and the stacker crane now runs straight at all times,” says Korpioja. The solution is based on the measurement of current, which allows the control system to detect when the stacker crane starts to move at an angle and correct the direction.

After the modernization, the stacker crane runs smoothly and softly, without any extra noises. Its movements are more under control, wear on parts is reduced, and the need for maintenance has decreased. According to Korpioja, the warehouse is now as good as new in terms of noise levels and flexibility of operations.

Added reliability for the stacker crane

BE Group praises Makron for seamless collaboration. “The project was a success: everything happened on schedule, and we were always up to date on what had been done and what was going to be done,” says foreman Jani Tyni. The stacker crane was fully operational just after the new year. Tyni appreciates the support provided by Makron during and after the project.

Thanks to the modernization, the components are state-of-the-art and spare parts are available when needed. The stacker crane moves smoothly and silently. Frequency converters feed braking energy from the stacker crane into the electricity grid, which saves energy.

After the modernization, BE Group’s staff can rely on the functioning and safety of the stacker crane under heavy use. “Its reliability has improved and there have been no additional outages,” says Hiltunen. The next project for BE Group and Makron is already being negotiated.

″It was great to see Makron’s ability to find solutions during the project. Makron has convinced me of its ability to handle projects.″

Petteri Korpioja

CEO

BE Group Oy Ab